Chi tiết nhanh

Dịch vụ sau bán hàng cung cấp: Kỹ sư có sẵn cho các máy móc dịch vụ ở nước ngoài

Warranty: life-time

Weight: 2800kgs

Điện áp: 220V hoặc 380V

Thương hiệu: EMM

Cấp giấy chứng nhận: CE

Dimension(L*W*H): 8000*9000*2350mm

Power(W): 34KW

Model Number: LZ-XC

Production Capacity: 500-10000 pairs/day

trạng thái: Còn mới

Feature 1: robotic injection, banana type

feature 2: mold open and close automatic

application: pu soles, safety shoes, slipper, sandals and other pu shoes

Raw material: polyurethane(=ISO+POLY)

required labor: 2~3 people

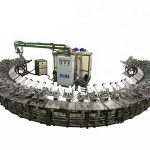

Máy làm giày an toàn PU Dây chuyền sản xuất chuối loại chuối

Ứng dụng sản phẩm

this equipment is used to produce polyurethane insoles, outsoles, high heels, leather shoes, casual shoes, safety shoes, travel shoes,slippers, sandals, flip flops and other all kinds of polyurethane shoes.

Product Component

this equipment includes one three components low pressure PU foam machine and one automatic banana-type production line. According to the client's production capacity, the production line has 24, 36, 60, 80,100,120 or other mold stations for choose.

SPECIFICATION | |||

Three-components inject machine | Item No. | EMM905 | |

Type of applicable foam | Sole,insole, walking shoe, etc. | ||

Flux of inject | 30g-100g/S (Attention:the flux could be configured) | ||

the mix proportion | 100-65;100-110 | ||

Process of injecting | Manual or automatic inject by PLC programmed for choose | ||

Dimension | Wide:2.1M; High:2.35M; Long:3.5M | ||

Weight of the machine | 1.5ton | ||

Pneumatic molds Production line | Pneumatic mold station | 24,36,60,80,100,120 mold station for choose | |

Mold station | Open and close automatically | ||

Material for work station | 3mm, iron plate | ||

Mold heating way | Water recycling system | ||

Water heating box | 150L,304 stainless steel | ||

Why choose it:

1. most of the components are imported, like the metering pump and electrical components, greatly enhancing equipment running reliability and service life;

2. the moulds can be opened and closed automatically by the pneumatic system which can Save the labor cost and around 2~4 people are required for the production only.

3. the molds are heated by circulating Water heating system, iT can Save 3/2 electricity compared with the traditional manual machine, it also makes the temperature of the molds stabler.

4. the injection can be or can not be robotic control, which is customized for the client.